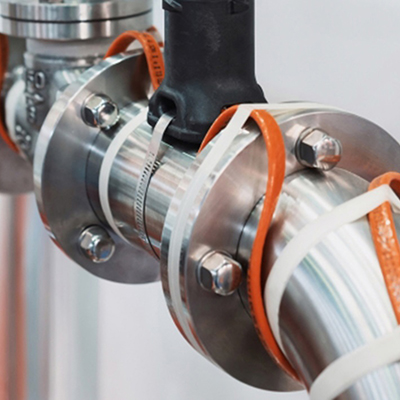

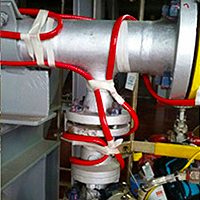

Trace heating, also known as electric heat tracing, is a cable/cord system used for process temperature compensation of pipes and structures in industrial applications. It involves wrapping the electrically powered heating cable or cord around the object to be heated. Trace heating elements are available in various forms of rating and sheath material for different temperature and process applications.

Self-regulating and constant wattage heater elements are commonly used for applications where pipes carrying liquids in some form need to be kept at specific temperatures to prevent the liquid from stalling (maintain a viscous state). Mineral insulated trace heater elements are generally applied for structures such as hoppers or vessels to maintain product temperature or expel moisture within the product housed within the structure. Our sales team is equipped to provide a suited trace heater best for the application.

Parallel circuit trace heating cable is supplied with a constant wattage output range between 20 and 60 watts per meter at any required length (limited to 60 meters). The trace heating cable incorporates twin insulated conductors with a spiral wound element connected to the conductor at 1000mm intervals with termination on one end of the heater cable. The outer jacket is either extruded silicone or fluoropolymer resin. These heating cables must always be temperature regulated either through a mechanical switching device (thermostat) or an electronic switching device (controller & sensor). Maximum application temperature output varies between 85-200° Celsius depending on cable selection.

Self-regulating trace heating cable is supplied at a wattage output range between 28 and 98 watts per meter at any required length (limited to 60 meters). The outer jacket of the heater cable is an extruded fluoropolymer resin and, in some instances, can be provided with a steel over-braid protection with termination on one end of the heater cable. These heating cables by nature of design self-regulate and don’t require additional temperature regulation. Depending on the heater cable selection, the maximum application temperature output varies between 65-95° Celsius.

FG CORD is a single-core trace heating cord with termination on each end of the cord. These heating cords are custom manufactured at various output ratings, ranging from 50 to 150 watts per meter and can be supplied to a maximum length of 30 meters. The heating cord is designed with a spiral wound or multi-stranded element with woven fibreglass over braided insulation suitable for higher temperature applications and environments. Maximum consistent application temperature is limited to 250° Celsius. Heating cords must always be temperature regulated either through a mechanical switching device (thermostat) or an electronic switching device (controller & sensor).

Mineral insulated (MI) trace heating cable is supplied at various resistances that in turn determine the rating (wattage) based on length. The typical power output ranges between 70 and 150 watts per meter depending on cable selection. The MI trace heating cable design incorporates a magnesium oxide (MgO) insulated element within a cupro-nickel or stainless-steel tubular outer sheath and a terminal on each end of the cable. These heating cables must always be temperature regulated either through a mechanical switching device (thermostat) or an electronic switching device (controller & sensor). Maximum application temperature output varies between 200-700° Celsius depending on cable selection.

Parallel circuit trace heating cable is supplied with a constant wattage output range of between 20 to 60 watts per meter at any required length (limited to 60 meters). The trace heating cable incorporates twin insulated conductors with a spiral wound element connected to the conductor at 1 000 mm intervals with termination on one end of the heater cable. The outer jacket is either extruded silicone or fluoropolymer resin. These heating cables must always be temperature regulated either through a mechanical switching device (thermostat) or an electronic switching device (controller & sensor). Maximum application temperature output varies between 85 - 200° Celsius depending on cable selection.

Self-regulating trace heating cable is supplied at a wattage output range of between 28 to 98 watts per meter at any required length (limited to 60 meters). The outer jacket of the heater cable is an extruded fluoropolymer resin and, in some instances, can be provided with a steel over braid protection with termination on one end of the heater cable. These heating cables by nature of design self-regulate and don’t require additional temperature regulation. Depending on the heater cable selection, maximum application temperature output varies between 65 - 95° Celsius.

FG CORD is a single core trace heating cord with termination on each end of the cord. These heating cords are custom manufactured at various output ratings, ranging from 50 - 150 watts per meter and can be supplied to a maximum length of 30 meters. The heating cord is designed with a spiral wound or multi stranded element with woven fiberglass over braided insulation suitable for higher temperature applications and environments. Maximum consistent application temperature is limited to 250° Celsius. Heating cords must always be temperature regulated either through a mechanical switching device (thermostat) or an electronic switching device (controller & sensor).

Click the link below to request a quote, get assistance or learn more about this product.

Contact us